As I haven't built a stool for a while, I decided to try my hand at a Shaker style bench / stool.

My scaffold boards have warped a fair bit in drying meaning a full bench was not really practical. Ok, I admit it, with a lot of planing it could be done, but my natural laziness told me to keep it small... hence I'm calling it a Shaker stool.

With some inspiration from Google images I rough cut my two side pieces of timber and attacked them with my winding sticks, a no#6 Foreplane set for a heavy cut followed by my no#7 Try plane set fine to get them flat.

After getting the edges straight and parallel, I cut the ends square on the bench hook.

I am definitely getting faster as milling rough sawn boards into usable stock.

The main feature of this stool is the cut out design of the side pieces. I first found the centre of the board and marked the position of my desired hole.

Now it's confession time... I didn't have an auger bit large enough and resorted to using .... A POWER TOOL!!!!!

Yep, I drilled my hole with my cordless drill and I feel dirty for it!...In fact it made everything dirty - what a mess it made. To make matters worse there was also a lot of tear out between the hard and soft wood in the grain.

Finally cutting out the connecting wedge shaped bit of wood with my large tenon saw. Now I had my sides, I needed a seat piece, more milling...

Soon it was beginning to look a bit like a stool...

Now I didn't have a plan and was just making it up as I went along, I had a loose idea of maybe some tenons in the side pieces coming up through the seat, but I didn't like the fact that the sides were the same width as the seat so there was no decorative overlap.

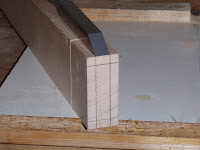

I didn't want to reduce the width of the side pieces as that would make the stool less stable. Where the side pieces meet the top piece looks clunky. What to do.... I decided I would have the side pieces rabbeted into the seat for strength and see what it looks like ...

Hmn... Still rather clunky. My only other option is to have the 'tenons' come up through the seat on the outside, thus hiding the joint. I marked and chiseled out the recesses in the seat top and used it as a template to mark up the side piece tenons.

I was finally happy with how the joint looked, now I just needed a 'cross brace' that would mortise and tenon through the side pieces. More milling...

With the brace all milled flat and true, I proceeded to cut the tenon on each end. Followed by the corresponding mortise in each side piece.

I was aware (after I finished the tenons) that I should have cut the mortises first to ensure that the tenons would be a tight fit ... luckily they weren't too bad.

It all fits... Now it's my favourite part of the project... NOT!

Glue Up... Take the phone off the hook, lock the door. Get everything ready... do a dry run first.

After gluing up the stool, it was just a matter of flush cutting off the protruding tenons, some final trimming and then applying a finish.

18 comments:

Well designed!! Simon. I think by tools we can make more different types of stuff for house. Just spend your money on tools and made your stuff with our own hands which make you happier when you put eye on them :).

tool venture products

Simon,

I am curious about the blue holdfasts. Are those shop made or purchases? If purchased, where? And do they work well?

Thanks,

Lance

Hi Lance - I got the 'holdfasts' from a farm supplies shop in France. They are very cheap, only a few euros each if I recall. I have never used 'real' holdfasts which fit 3/4" holes to compare but these work quite well in my beginner workbench.

I get the impression that they are a common tool used by the French as I have seen them a few times in various hardware store type places. They have a spike on the bottom and the arm that holds the work 'floats' on the shaft. I may not even be using them for their intended purpose - but they are cheap and they work...

I bought holdfasts from top US store but you made it very nice with great idea.

Quality Furniture For Less

your blog is excellent....I really liked your blog, appreciate the great information about Hand Tools.

Nice blog, and nice work, sir.

I found your site while looking for information on sawbenches. How is yours holding up? Particularly curious about the glue-only joints in the top - did you every find the need to add screws or other mechanical fastners?

see my video about woodwork

Woodworking Plans

To learn how you can download over 16,000 woodworking plansClick Here

Cool Design, Hand Tools can really help us to design our own. Thanks for Sharing.

Great project! Have you ever used a Makita brushless for your any project?

Nice blog post!

your blog content is good about all things and intresting word. thanks for sharing...

cnc machinery

Extremely useful simple elements given by you here, this publish without doubt makes clear crucial ideas to its visitors. A debt of appreciation is to be able regarding continuous to make such amazing content...

Jody

We are Trusted Manufacturer and Supplier of High Quality TUFF Scaffolding Tools, Tube Straightening Machines, TUFF System Scaffmarking Machine, TUFF Scaff Tube Marking Machine .Huge range of quality scaffolding tools at discount prices!

Why is the shaker stool called so? I really like the joint cuts and it's a great looking stool. I will certainly give it a go at some point. Thanks for the post. If you happen to need a really good Cnc company for any of your projects I really recommend these guys - Cnc Routing

Download over 16,000 WOODWORKING Plans at here http://woodworkingplanspro.weebly.com

Woodworking guide offers anyone of any skill level the ability to build amazing projects. The guide is extra helpful because it offers more detailed explanations, videos and blueprints then your typical woodworker magazine.

Arbor Projects ,

Adirondack Chairs ,

Artwork Display ,

Bathroom Unit ,

Box Designs ,

Billiard/Pool Table ,

Barn Plans ,

Bed Plans ,

Bedside Cabinets ,

Bee Hive Plans ,

Bench Projects ,

Bird Feeders ,

Birdhouse Plans ,

Boat Plans ,

Book Case Plans ,

Baby Changing Table ,

Coat Rack ,

Cabin Plans ,

Cabinet Plans ,

Carport Plans ,

Cart Plans ,

Cat House Plans ,

CD/DVD Holder ,

Cellar Projects ,

Chair Plans ,

Chest Designs ,

Chicken Houses

Childrens Room Plans ,

Clock Plans ,

Coasters ,

Coffee Table Designs ,

Cold Frame Plans ,

Compost Bin ,

Computer Desk ,

Containers ,

Cradle Projects ,

Small Crafts ,

Cutting Board ,

Deck Plans ..

Each man needs space in a home to call his own, generally alluded to as a "man buckle". Regardless of whether it is an office, cave, amusement room or even the carport, bar stools can add to the manly feel of a room. I find a very good website for the Best palm sander reviews, If you want you can visit this site.

Really good I impressed about you blogs so I would like to talk about it click>>Howe Tools Coupon Codes to get amazing offers.

Post a Comment